Hello, Welcome to Changzhou Jingzhu Drying Equipment Co., Ltd. Website!

Home

Home  Contact us 中文

Contact us 中文

Hello, Welcome to Changzhou Jingzhu Drying Equipment Co., Ltd. Website!

Home

Home  Contact us 中文

Contact us 中文

Changzhou Jingzhu Drying Equipment Co., Ltd.

Add: Sanhekou Industrial Park,Zheng Luzhen,Changzhou City,Jiangsu Province

Tell: 0086-51989627708

0086-519-89627738

Fax: 0086-519-89627718

Contacts: Lu Huanbiao

Mob: 0086-13861278173

E-mail: jz@jzdry.com

>Your position : Home > Products > Granulation equipment series

product description

The unit is a device that can be dried and pelletized at the same time. According to the process requirements can adjust the material pump pressure, flow, the size of the nozzle, get the required size of the spherical particles.

The working process of the unit for the material through the diaphragm pump high-pressure input, sprayed droplets, and then with the hot air co-current decline, most of the powder from the bottom of the collection port collection, exhaust and its fine powder by cyclone separation , The exhaust gas from the exhaust fan, the powder by the cyclone separator at the bottom of the pollination tube collection, fan outlet can also be equipped with secondary dust removal device, the recovery rate of 96-98% or more.

The unit and the material contact part of the tower body, pipe, separator material, are used SUS304 production. There is sufficient moisturizing layer between the inside of the tower body and the shell. The filling material is ultra-fine glass wool. The tower body is equipped with observation gate, sight glass, light source and control instrument, controlled and displayed by the electrical control console.

Applications

Pharmaceuticals: cocoa, coffee, milk powder, granular fruit juice, condiments, etc .; other industries: pesticides, feed, fertilizer, pigments, dyes and so on. Other industries: pesticides, feed, fertilizer, pigments, dyes and so on.

Features

1, the drying speed, the material after the atomization of the surface area greatly increased in the hot air flow, the instant can be evaporated 95% -98% of the water to complete the dry time only need ten seconds to several seconds, especially Suitable for the drying of heat-sensitive materials.

2, all products for the spherical particles, uniform size, good mobility, good solubility, high purity products, good quality.

3, the use of a wide range, according to the characteristics of the material, you can use hot air drying, you can also use cold air granulation, the adaptability of the material.

4, simple and stable operation, easy control, easy to automate operations.

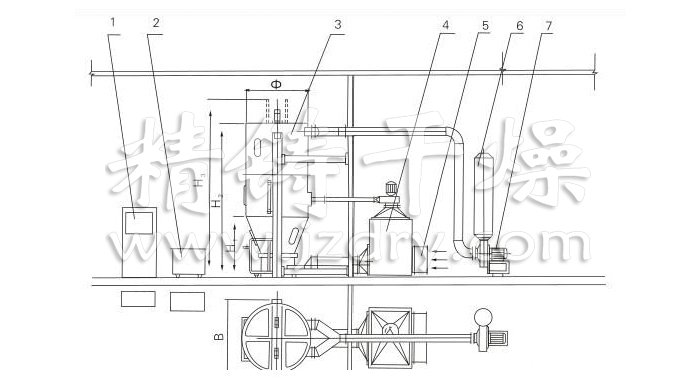

Schematic

1, control cabinet 2, infusion trolley 3, host 4, heat exchanger cabinet 5, sub-high efficiency filter 6, muffler 7, induced draft fan

技术参数

| Project | Unit / model | PGL-3B | PGL-5B | PGL-10B | PGL-20B | PGL-30B | PGL-80B | PGL-120B | |

| Flow extract | Minimal | kg/h | 2 | 4 | 5 | 10 | 20 | 60 | 100 |

| Minimal | kg/h | 4 | 6 | 15 | 30 | 40 | 100 | 140 | |

| Boiling ability | Minimal | kg/批 | 2 | 6 | 10 | 30 | 60 | 100 | 150 |

| Minimal | kg/批 | 6 | 15 | 30 | 80 | 160 | 250 | 450 | |

| Liquid specific gravity | kg/L | ≤1.30 | |||||||

| Raw material container volume | L | 26 | 50 | 220 | 420 | 620 | 980 | 1600 | |

| Container diameter | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 | |

| Induced fan power | kw | 3.0 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | |

| Auxiliary fan power | kw | 0.35 | 0.75 | 0.75 | 1.20 | 2.20 | 2.20 | 4 | |

| steam | Consumption | kg/h | 40 | 70 | 99 | 210 | 300 | 366 | 465 |

| pressure | Mpa | 0.40-0.60 | |||||||

| Electric power | kw | 9 | 15 | 21 | 25.5 | 51.5 | 60 | 75 | |

| Compressed air | Consumption | m3/min | 0.5 | 0.8 | 0.8 | 0.9 | 1.1 | 1.3 | 1.8 |

| pressure | Mpa | 0.40-0.60 | |||||||

| Operating temperature | °C | Room temperature -160 ° C automatic adjustment | |||||||

| Product moisture | % | ≥0.2 | |||||||

| Material yield | % | ≥99 | |||||||

| Equipment noise | dB | <77 | |||||||

|

Host size |

Φ | mm | 400 | 550 | 770 | 1000 | 1200 | 1400 | 1600 |

| H1 | mm | 940 | 1050 | 1070 | 1220 | 1570 | 1590 | 1690 | |

| H2 | mm | 1900 | 2360 | 2680 | 3150 | 3630 | 4120 | 5050 | |

| H3 | mm | 2050 | 2590 | 3020 | 3600 | 4180 | 4770 | 5800 | |

| B | mm | 740 | 890 | 1110 | 1420 | 1620 | 1820 | 2100 | |

Example: Requires each batch to deal with the amount of flow extract I = 120kg (solid content of 30%), seed weight II = 60kg, I, II can be obtained from the theoretical yield M = mI + mII = 120kgx30% +60kg = 96kg, working time T = 120kg / 30kg / h = 4h, the technical parameters column can be found in the boiling volume of the standard load range, so the completion of two batches per class, the choice of PGL-30 type is more appropriate.

Add:Sanhekou Industrial Park,Zheng Luzhen,Changzhou City,Jiangsu Province Tell:0086-519-89627708 0086-519-89627738

Fax:0086-519-89627718 Contacts:LuHuanbiao 0086-13861278173 E-mail:jz@jzdry.com

Copyright © 2017 Changzhou Jingzhu Drying Equipment Co., Ltd. Legalnotice Design : EastNet [Manage]